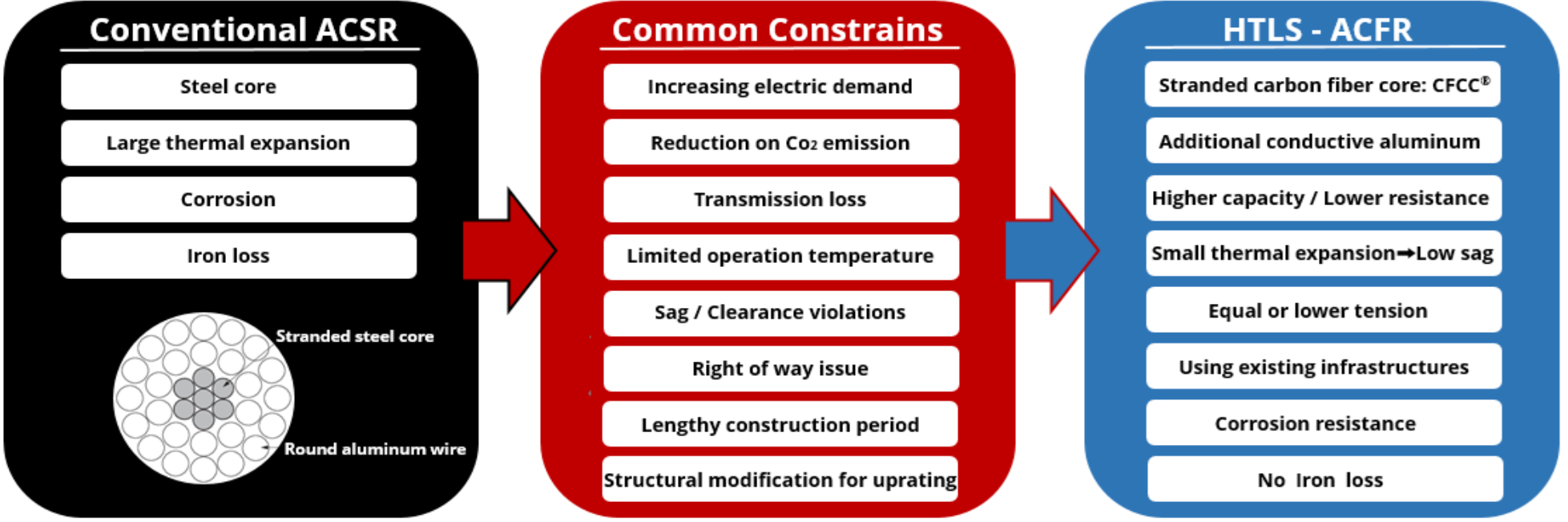

Flexible and Durable goes far

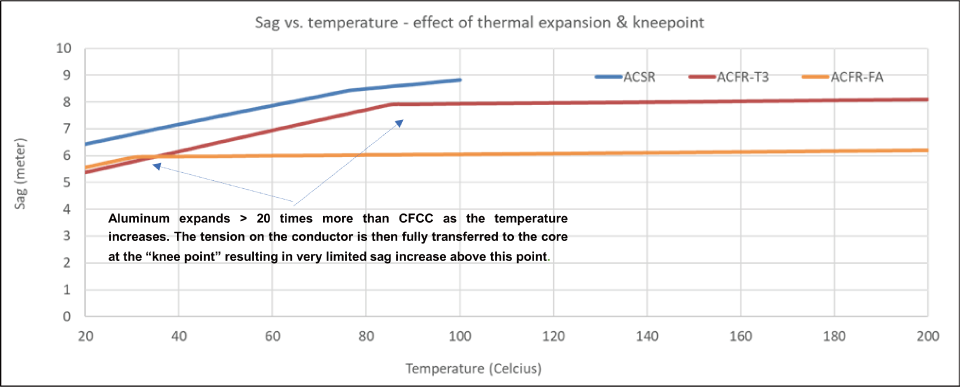

- Thermal Expansion - minimal sag increase at high power transfer

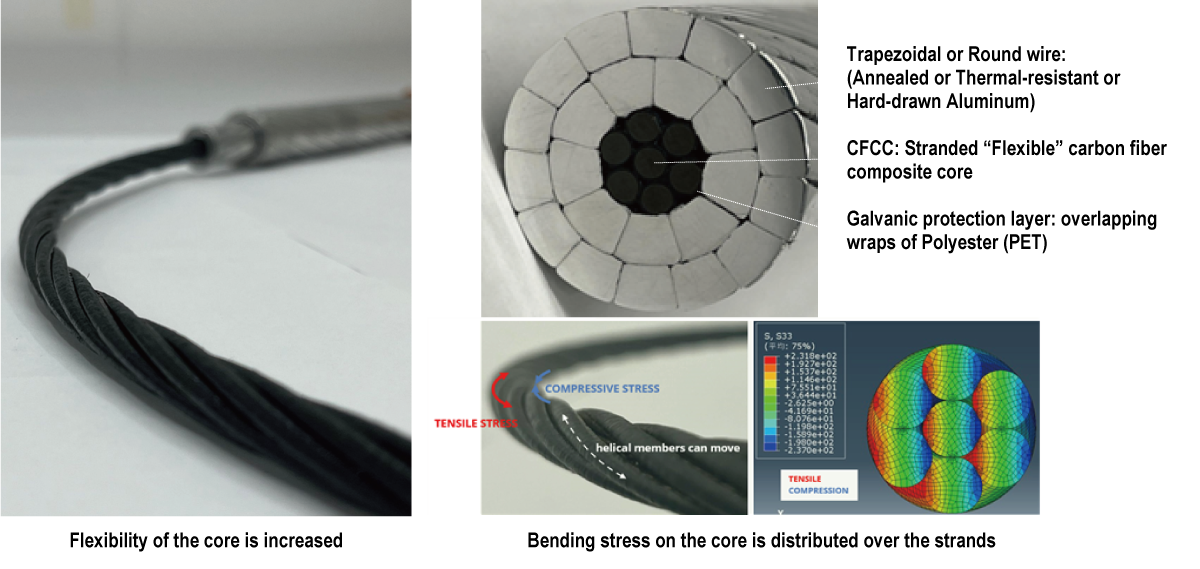

- Stranded Core - flexible, robust and rugged. No single-point-of-failure

- Easy Installation - install like ACSR, using conventional methods

- Compression-type fittings - familiar hardware

- Designs for all loading conditions - long span, light load to heavy ice load

- Trapezoidal wire(TW) or Round wire available - optimized design options

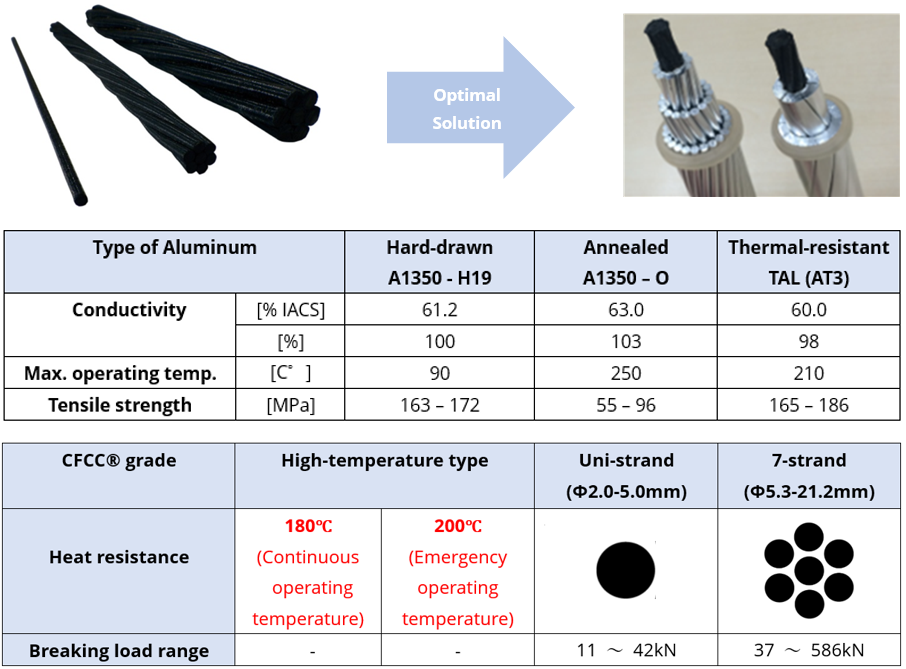

- Annealed (1350-O Temper) or Thermal-resistant or Hard-drawn Aluminum

How does ACFR® work?

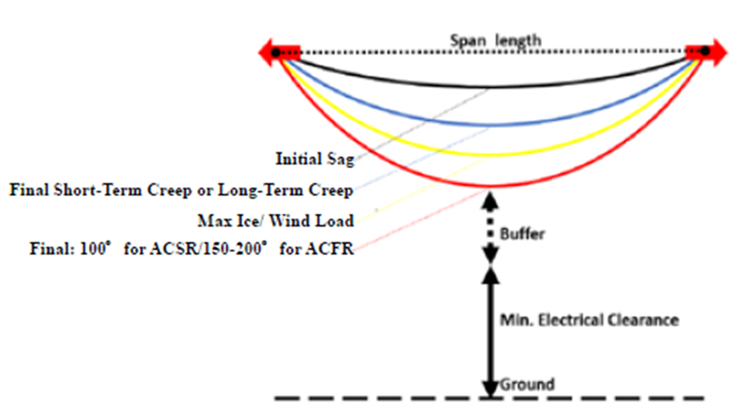

Lighter ACFR can be installed higher than ACSR at the same tension which results in more room for initial sag

Until the kneepoint, the thermal expansion is almost the same for ACSR & ACFR (governed mainly by the aluminium expansion), and above the kneepoint of ACFR there is almost no further thermal expansion (fully governed by CFCC)

The kneepoint of ACFR-FA with fully Annealed aluminium is very low and lowest sag or highest capacity can be acheived

For extreme ice or wind load, a thermal alloy may be needed for increased modulus of elasticity and strength.

What is the expected lifetime of the ACFR® conductor?

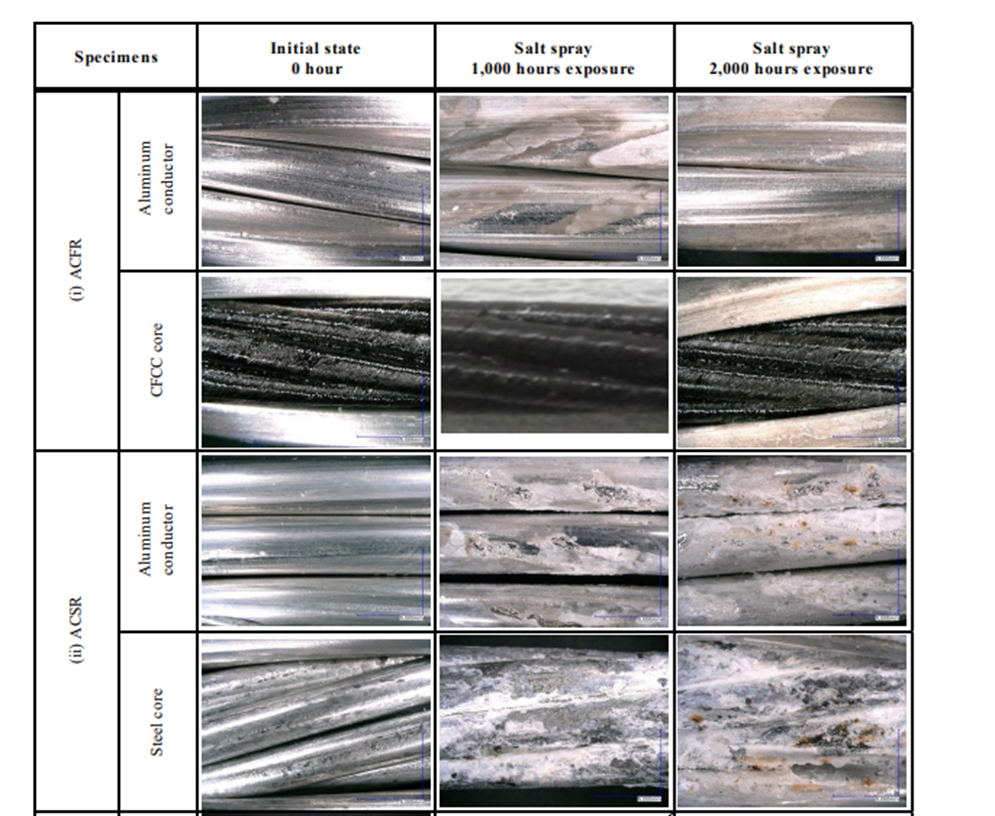

Carbon fiber itself is non-corrosive and degradation of CFCC core that results in tensile strength reduction during the course of its lifecycle is minimum.

The expected lifetime of ACFR® conductor exceeds that of ACSR.

Galvanic Protection

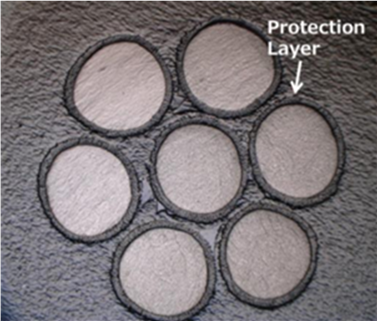

- Galvanic corrosion occurs when two conductive materials are met with electrical contact in the presence of an electrolyte, most commonly water.

- Polyester yarn (PET) functions as a physical barrier between the carbon fiber and aluminum to prevent electrical contact.

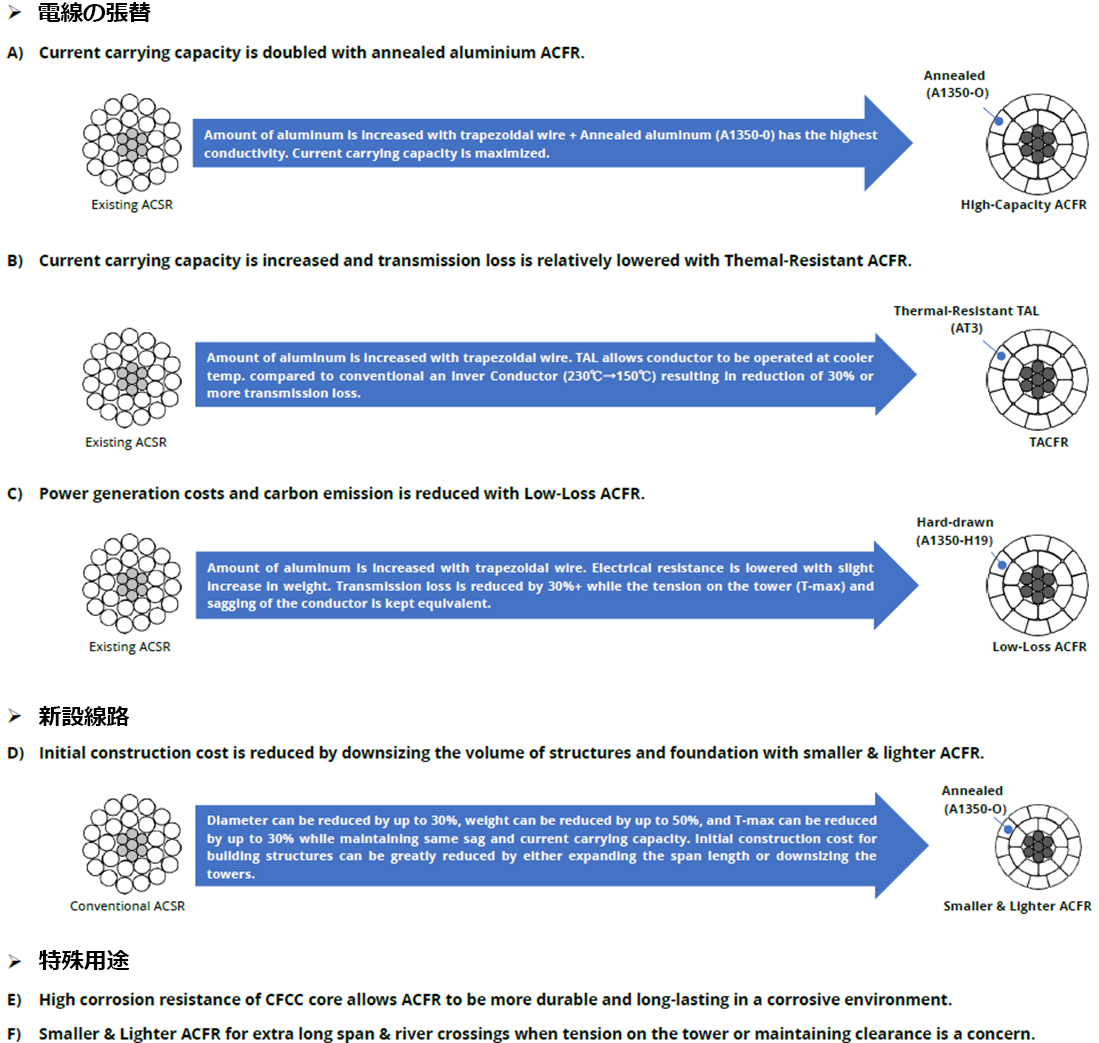

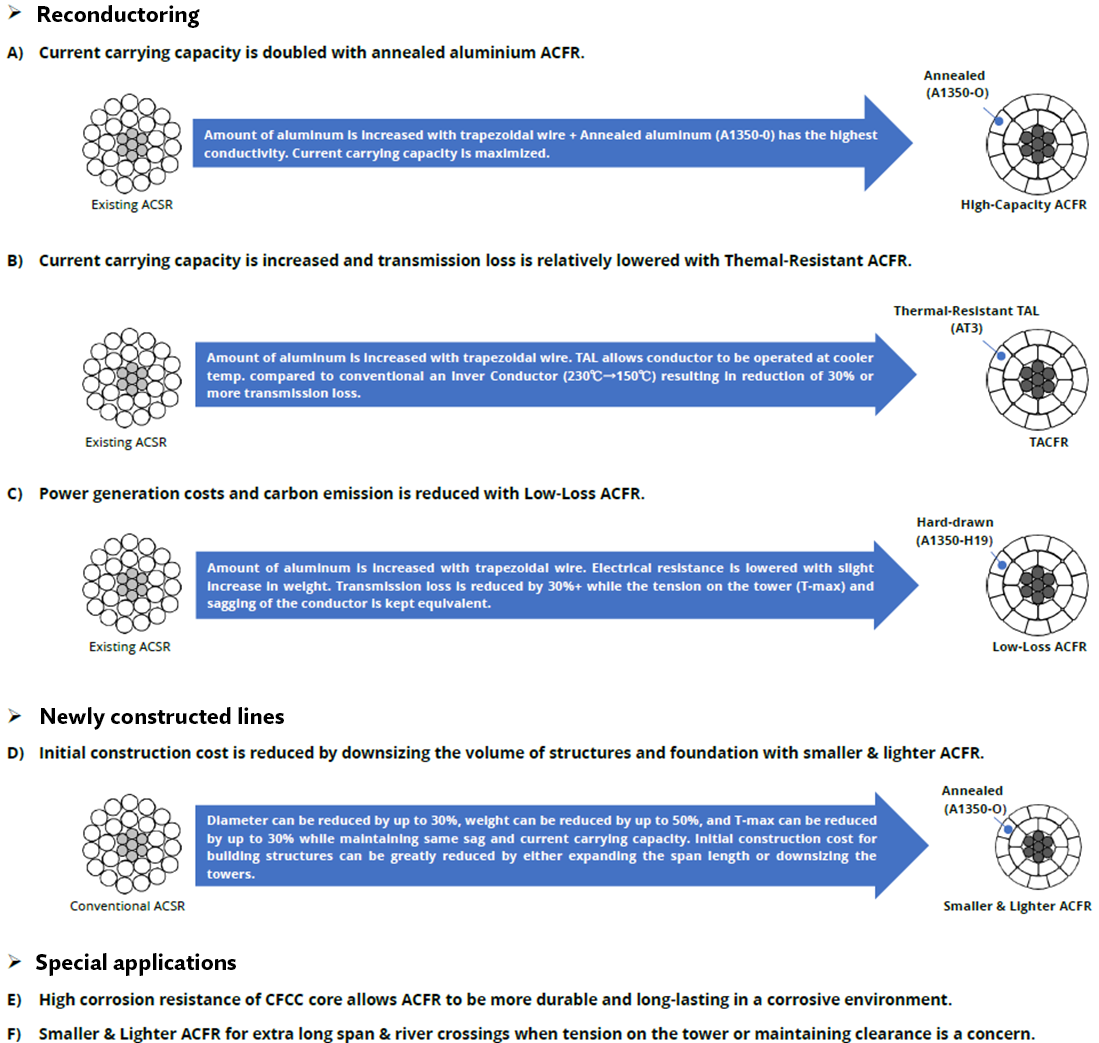

Applications®

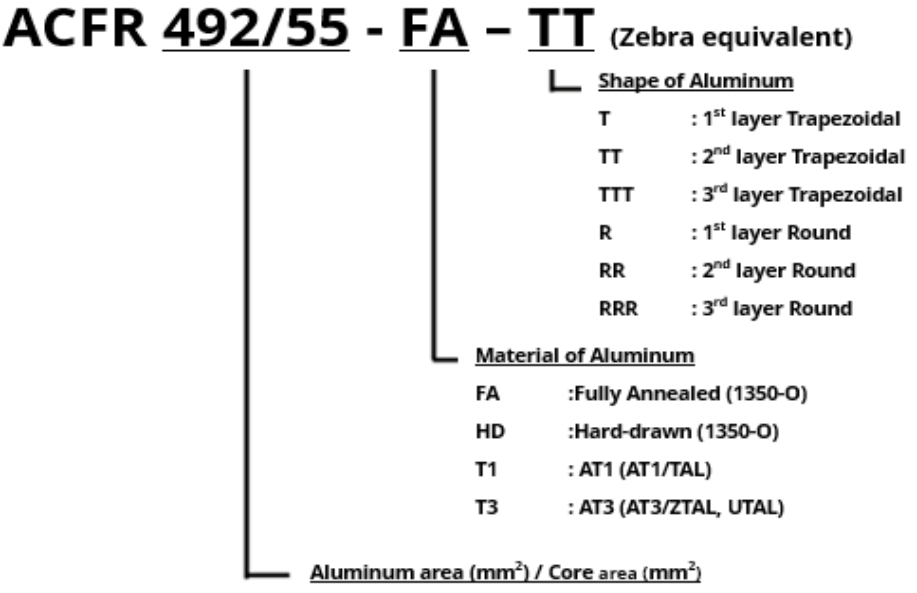

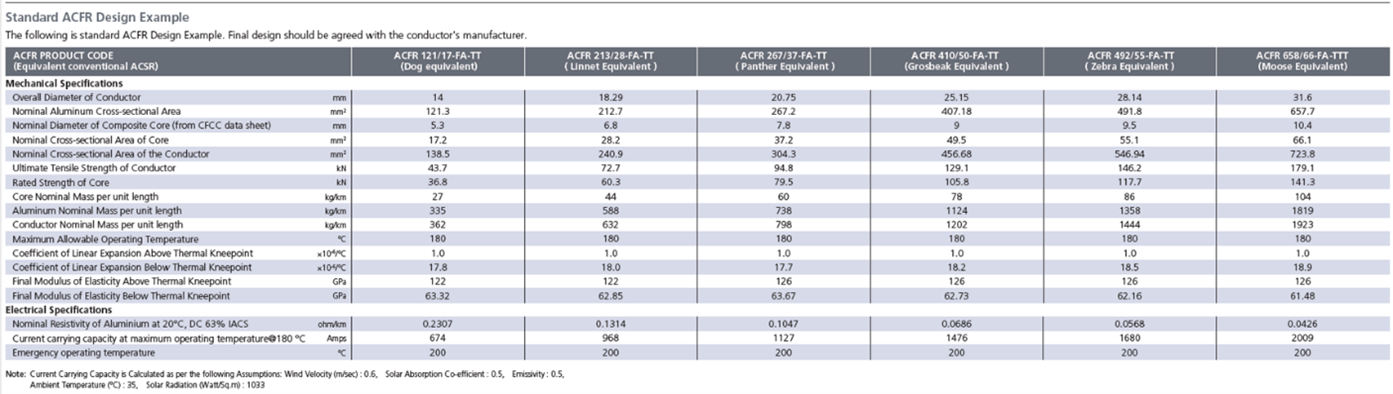

Design Option

- Round or trapezoidal shaped wires with 20% more aluminum or 10% smaller diameter.

- Annealed Aluminum Highest conductivity. low tensile strength

- Thermal-resistant Aluminum Moderate conductivity, high tensile strength

- Either type of Aluminum can be used for ACFR depending on requirement