Manufacturing of Carbon Fiber Composite Cable - CFCC®

Our patented CFCC® core was developed by incorporating sophisticated stranding technology and modern materials science.

It is an object of the technology to provide a carbon fiber composite core having increased flexibility, suitable workability, better damage tolerance, and structural redundancy without a handling characteristics penalty.

Unlike the pultrusion process, stranding carbon fiber requires technical know-how with precision and consistency, and we have reasons to believe that practical handling characteristics and better damage tolerance should be prioritized.

Stranded CFCC® has served in civil engineering applications for 30 years and in overhead conductors for over 20 years.

Stranded CFCC® has served in civil engineering applications for 30 years and in overhead conductors for over 20 years.

Carbon fibers

CFCC®

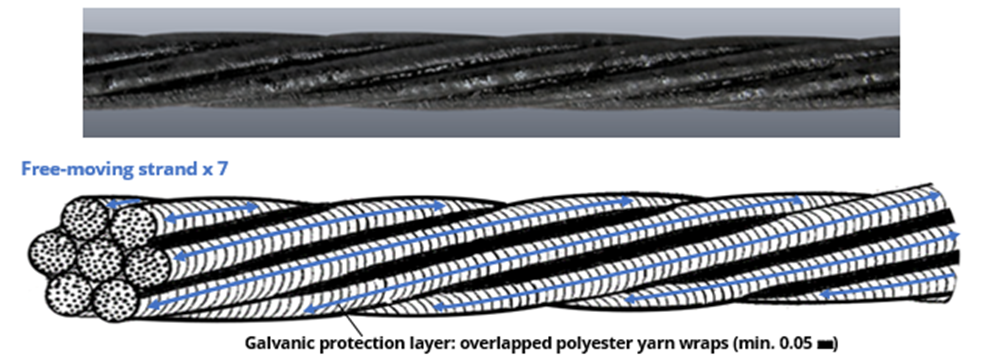

- Uni-directional carbon fibers stranded in a thermoset epoxy resin matrix

- Carbon fiber grade is T-700 or higher. Each strand consists of 12,000 filaments

- Protection layer: overlapping wraps of polyester yarn (PET) covers each strand for mechanical and electrical protection

CFCC® after heat treatment

Quality Control of CFCC®

- Samples of CFCC® are tested to make sure that they meet or exceed all product specifications. Testing includes various physical, mechanical, and chemical test.

- Tested CFCC® is carefully packaged and shipped to our stranding partners who manufacture ACFR® which is ultimately shipped to end users.

Manufacturing of Conductors and Providing Technical Support

- Our partners are experienced stranders with proven capabilities to manufacture ACFR® conductors.

- Our experts can also support new stranding partners who wants to diversify product line-ups by providing technical support to start production of ACFR® conductor, initiate a track record with a pilot line, and progressively move on to full implementation projects.

- Our experts can also support new stranding partners who wants to diversify product line-ups by providing technical support to start production of ACFR® conductor, initiate a track record with a pilot line, and progressively move on to full implementation projects.

- We also provide on-site training and installation support services to ensure that the optimal solution is fully realized by end users.